OLAER (Switzerland) AG was founded in 1969 in Colombes (F) as a fiduciary of OLAER Indus-tries SA. It was in 1976 that we were able to move to the facilities where we are currently locat-ed, in Düdingen (in the Canton of Fribourg).

On the 1st of July 2012 the worldwide active OLAER Group was taken over by Parker Hannifin Cleveland. On the 1st of January 2013 OLAER (Schweiz) AG was bought back by its management and became a certified Parker distributor for hydraulics.

Olaer (Schweiz) AG currently employs staff in Switzerland, Germany and Austria. With its products and services in the fields of hydraulics, water and wastewater technology the company ranks among the market leaders in this country. OLAER focuses on new innovative and sustainable industrial and infrastructural products, which are systematically developed further.

Accumulators

|

AC, IHV, NG, and ELM Series AC, IHV, NG, and ELM Series Accumulators incorporate the lates design and material technologies to improve performance and reliability of the accumulator when it is used in heavy duty application or under severe working conditions |

ELM Series

Operation of the OLAER gas loaded diaphragm accumulator is bassed on the considerable difference in compressibility between a gas and a liquid, enabling a large quantity of energy to be stored in

an extremely compact form. This enables a liquid under pressure to be accumalated, stored and recovered at any time.

Model VGU

Universal charging set fits most of the hydraulic accumulators available on the market. Maximum working pressure: limited by the maximum operating pressure of the installed pressure limted to 400 bar in any case.

Safety Blocks

Are designed to incorporate in a single compact block a variety of functions necessery for the correct operation of

a hydraulic system fitted with accumulators. This includes manual and/or electrical drain, isolation, flow control and pressure relief.

Bladder Accumulator AC, IHV, NG Series and ELM Series

Coolers

PWO Series

Plate water Oil cooler are the modern variant of the traditional shell and tube cooler. Unlike other plate cooler on the market mostly produced for water, steam or chemical applications, the internal structur of the OLAER Fawcett Christie PWO is designed to provide the highest efficiency while offering the lowest pressure drop required for the oil in hydraulics and lubrication applications.

SHELL AND TUBES

Although not as efficient and compact as the Plate Water Oil cooler, Shell and Tubes coolers are still extremely popular in various types of industries. OLEAR Fawcett Christie therefor strives to find the best possible design that would combine a limited water flow rate with a maximum efficiency.

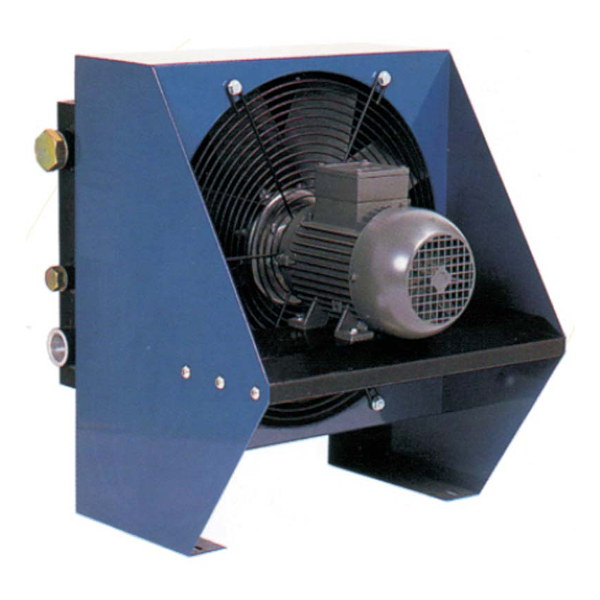

Air Oil Cooler

ECO, LAC, LDC, LHC and LOC series

– AC and DC motor available

– Cooler matrix with low pressure drop and high cooling capacity – Simply and user friendly design